Team ZX1 is an eco-friendly metal lubricant company from the UK, founded in 1992 and renowned for pioneering friction reducing technology. We are the developers of Extralube ZX1 Micro Metal Treatment, a premium lubricant that bonds at the microscopic level to metal surfaces to virtually eliminate wear. This flagship product was born from a mission to improve engine efficiency and durability while minimizing environmental impact.

Over the decades, ZX1 history has been defined by technical excellence, sustainability, and a drive to push the boundaries of UK oil treatment innovation. Below, we share our journey from humble beginnings to a globally recognised brand.

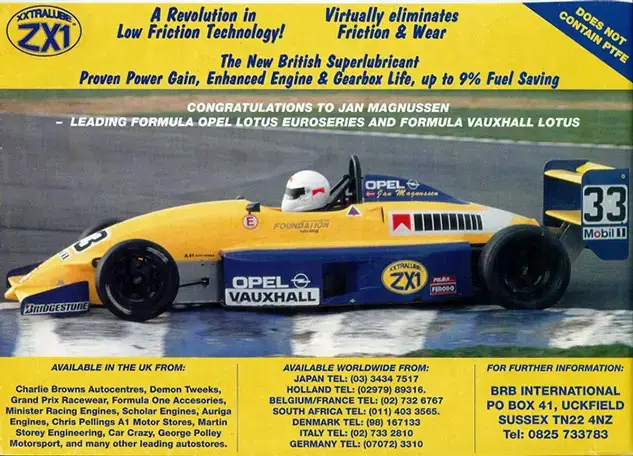

In the early 1990s, our founders began experimenting with advanced lubricants under the name BRB International. They saw a demand for a new kind of metal treatment—one that could provide long-term protection under extreme conditions. After years of R&D and field trials, Team ZX1 officially launched in 1992 to introduce a revolutionary solution: Extralube ZX1 Micro Metal Treatment.

We started small, blending prototype formulations and partnering with local motorsport teams to prove the concept. In those early days, we had few customers but a great idea – a micro metal treatment that produced outstanding results. By giving samples to racing teams and gathering their test feedback, we refined the formula into the ZX1 treatment we know today. This hands-on collaboration with engines and gearboxes in real racing conditions helped shape a lubricant unlike any other.

One pivotal moment in our origin story came on the racetrack. Touring car driver Yvan Muller (driving for Omegaland Racing) encountered a severe gearbox lubrication pump failure during practice. With no spare pump available, his engineer added our ZX1 treatment to the repaired gearbox. During the race after only one lap of the Grand Prix circuit at Brands Hatch the pump failed again but by this stage the zx1 had treated the gearbox and he won the race without proper lubrication. Competitors were astonished – they expected his car to fail, but ZX1’s technology saved the day. This triumph under extreme stress wasn’t just luck; it was proof of our innovation’s effectiveness.

It kick-started a long and successful association between Team ZX1 and motorsport, demonstrating that our fledgling company’s lubricant could deliver under the toughest conditions. From that point on, we earned a reputation among racing professionals for solving problems that traditional oils couldn’t, cementing our early credibility.

At the core of Team ZX1’s success is Extralube ZX1 Micro Metal Treatment – an innovation that redefined engine and machinery lubrication. Unlike typical oil additives that merely mix with oil, ZX1 is a “friction eliminator” that chemically bonds to metal surfaces at the molecular level. This micro-treatment does not alter the oil’s properties; instead, it uses the oil as a carrier to reach internal metal parts, where it then forms a protective, ultra-smooth layer on the metal itself.

By smoothing microscopic asperities on metal surfaces, ZX1 dramatically reduces friction and wear. The result is a virtually friction-free environment that allows any engine or mechanism to operate more efficiently. Users immediately notice benefits such as lower heat and noise, improved power output, and excellent cold-start protection, as well as extended component life and reliability. In fact, one single treatment can protect engine parts for up to 25,000 miles of driving.

From the beginning, our technical approach has been about science and quality. ZX1’s formula is a non-particulate micro metal treatment technology – it contains no solid particles like PTFE (Teflon) or molybdenum disulfide, which are found in some additives. By avoiding such ingredients (which can clog filters or alter tolerances), we created a clean, eco-conscious lubricant. ZX1 has a toxicity level comparable to common substances like milk or garden soil, making it safer for users and the environment.

This chemistry is also non-corrosive to copper and other engine components. In essence, our metal treatment pioneered a more elegant solution to friction: rather than adding heavy polymers or harmful chemicals, ZX1 uses advanced surface-modifying technology to enhance the oil’s lubricity naturally. This UK metal treatment innovation not only reduces friction and wear, but also yields broader benefits – lowered exhaust emissions and improved fuel economy, contributing to a smaller carbon footprint. We’re proud that ZX1’s innovation embodies both high-performance engineering and eco-friendly values, satisfying the technical demands of industries and the sustainability expectations of modern consumers.

Today, Team ZX1 stands as a worldwide leader in friction reduction and metal surface protection. From our UK headquarters, we serve clients globally. Whether it’s helping a family car run smoother or ensuring a generator avoids costly downtime, ZX1 products deliver reliability and excellence.

We supply to B2B partners like workshops, haulage firms, marine fleets, and power companies, as well as to B2C customers using our treatments in personal vehicles, motorcycles, or hobby engines.

Despite our global reach, our original mission remains unchanged: to champion an eco-friendly approach to lubrication. By reducing friction, our products help machines run more efficiently, consuming less fuel and emitting fewer greenhouse gases. They also extend the lifespan of mechanical parts, reducing waste and the need for replacements.

We carry NATO stock number, reflecting our commitment to rigorous production standards. Just as importantly, we value the trust of every customer – each bottle and tube we produce is the result of science, testing, and a promise of performance. Our story of UK oil treatment innovation is still being written, and we continue striving to make friction a thing of the past.

If you need help choosing the right ZX1 product or want expert guidance, don’t hesitate to contact us. We’re here to help you make the best decision for your vehicle, equipment, or fleet.

Contact US

Enjoy unbeatable benefits when you order direct:

Whether you’re a distributor or retailer, we’re here to power your performance with premium lubrication technology.

Apply today and become a Trade Partner.

Your experience matters to us. If you’ve recently purchased a ZX1 product or interacted with our team, we’d really appreciate it if you could leave us a quick review. It only takes a moment, and your feedback helps us continue to improve and support other customers with confidence.

CLICK HERE TO LEAVE YOUR REVIEW“EXTRALUBE ZX1 does not contain any solids it is ideal for using in hydraulic systems to reduce running temperature and improve efficiency by reducing internal friction thereby improving component life.

To use EXTRALUBE ZX1 in hydraulics we advise a 1% ratio of ZX1 to Hydraulic oil, if possible, bypass the hydraulic oil tank and introduce the ZX1 directly into the working part of the system which will ensure that the ZX1 gets to the working parts quicker.

In the past we have witnessed the following, a JCB with a concrete breaker attached was running at 7/8ths throttle to acquire the ideal breaking action, 1% of EXTRALUBE ZX1 was introduced to the hydraulic oil tank, within +/- 15 minutes the throttle was backed off to 5/8ths retaining the same breaking action.”

“Yes, ZX1 Grease can be used on bearings. It is a high-performance grease that provides excellent lubrication and protection for various types of bearings, including ball bearings, roller bearings, and plain bearings. It can help reduce friction, prevent wear, and extend the lifespan of the bearings.”

“Yes, We suggest you spray the chain with C60 ZX1 Extralube, this will help loosen any rusty parts and help free jammed mechanisms, it will also keep the chain in good shape and reduce drag; some of our customers have remarked that it dramatically reduces chain stretch.”

“Yes, we have customers using on all type of bearings including skate bearings. Any difficult to access area will benefit from a drop of this highly versatile oil.”